Reverse Engineering of a 0.68 Caliber Semi-Automatic Paintball Marker

Project Objective:

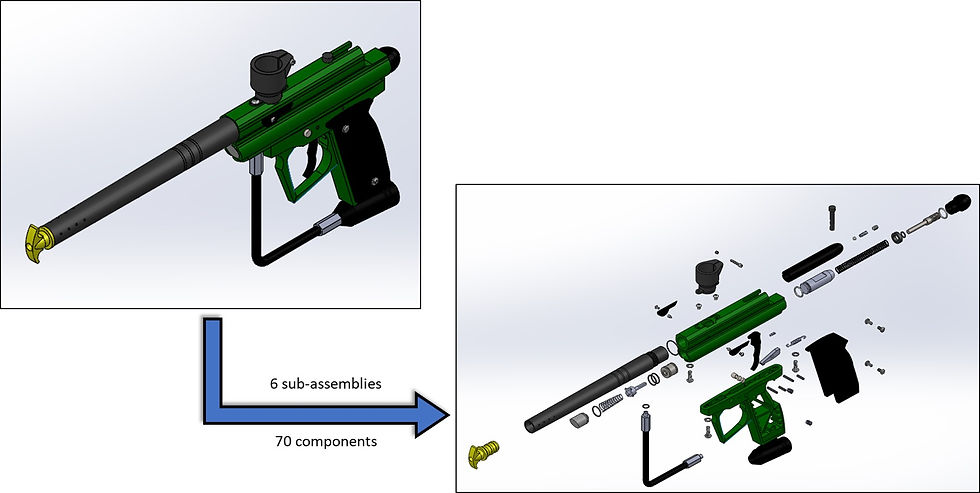

To reverse engineer a fully-mechanical object, we undertook a paintball marker which is a very exciting and a popular consumer product across a wide age-group. The objective of the project was to "Reverse Engineer the product and suggest improvements in parts manufacturability & assembly, to reduce the part count based on DFMA principles".

My Role:

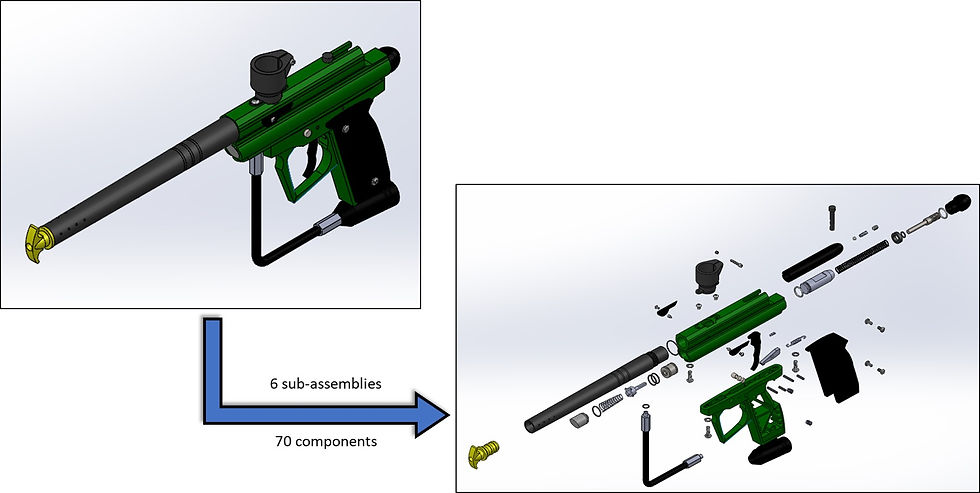

The project started with a step-by-step disassembly of the product containing 70 parts, analyzing each and every part for its design and assembly relations. A further investigation was done on the material and manufacturing choices, followed by estimating the cost of all parts. Finally, a DFA analysis was implemented to identify potential improvements in terms of error-proofing, handling, insertion and secondary operations.

Results:

A total of 6 design improvements were suggested which reduced the part count by 14. One process improvement was suggested that reduced the assembly time by 20 seconds behind every product. Because of all these changes, the total manufacturing cost of the paintball marker was decreased by $13 (roughly equivalent to 20% of selling price).

Project Contributors:

Team Members: Daniel Kim, Sourabh Chikode, Swapnil Kumar

Project Mentor: Prof. Dan Riffell