Machine Design - DFM & DFA

Design and Development of an Industrial Pomegranate De-Seeding Machine - Padmatech Industries

Project Objective:

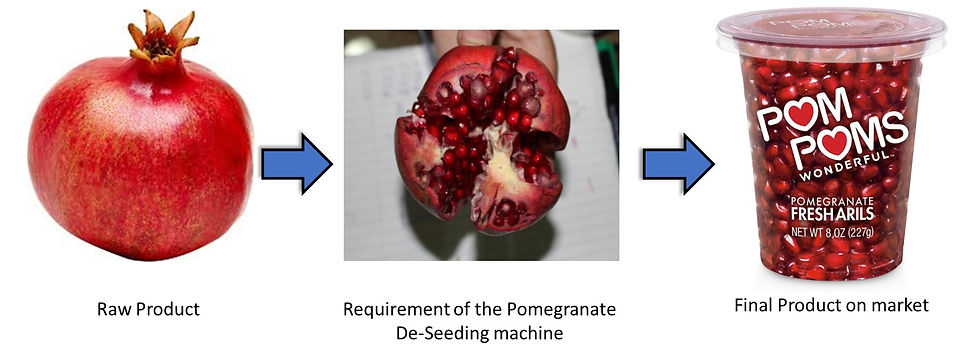

Undamaged and intact red seeds (aka arils) of a pomegranate are in a great demand in the pharmaceutical, cosmetic and frozen food industry. Detaching them from the outer skin with bare hands is a time-consuming and unhealthy process. Padmatech Industries already had a machine with a high production rate, but with a high damage rate. The task assigned was to "Develop an improved robotic mechanism that effectively separates the arils without damaging/crushing them".

My Role:

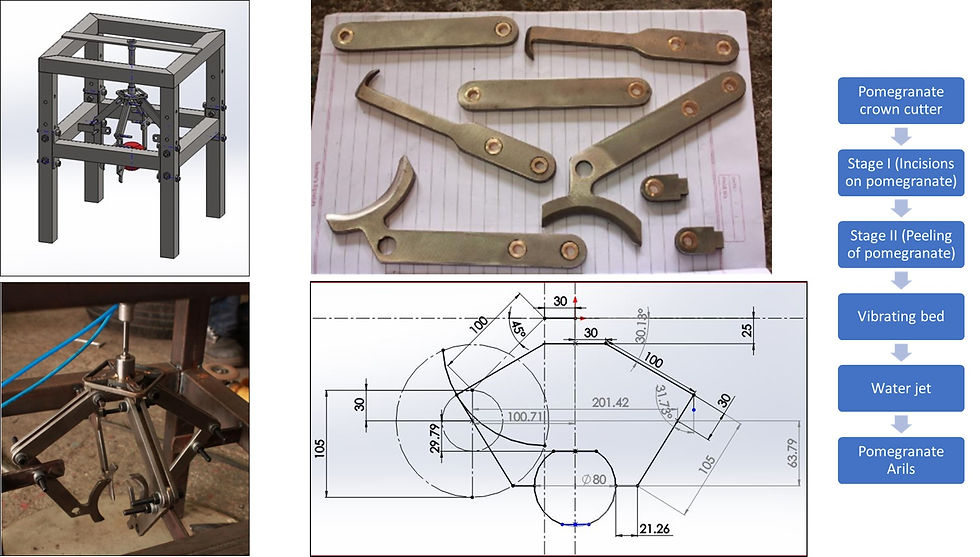

As a Product Development Engineer on the team, I worked towards understanding the design, build, flaws of the existing machine and identifying areas of improvement to fit into the client's modified requirements. It was followed by brainstorming new concepts altogether and selecting one based on feasibility, manufacturability and cost. I developed the static and dynamic configurations of the 4-arm robotic gripper mechanisms, while also making provisions to accommodate variability in fruit sizes. All components were designed based on DFMA principles and for easy removal of end-blades for replacement & cleaning. In this process, I got to interact with the QA team to follow Food Industry standards, production staff to manufacture custom components and external vendors to source materials and fasteners.

Results:

The new design increased the efficiency by 25%, where only 5% of the seeds from 1 fruit were getting damaged. The power consumption was significantly reduced by 40% by using pneumatic actuators instead of electric motors. Also, the entire manufacturing cost of the new machine was 75% lower than the previous machine.

Project Contributors:

Team Members: Yash Dandavate, Aishwarya Lele